Residual Stress Measurement

Stress-Space Ltd specialises in determining surface and volumetric maps of residual stress in engineered structures using the measurement technologies listed below:

adaptive X-ray neutron diffraction contour method residual stress measurement adaptive X-ray neutron diffraction contour method residual stress measurement adaptive X-ray neutron diffraction contour method residual stress measurement adaptive X-ray neutron diffraction contour method residual stress measurement

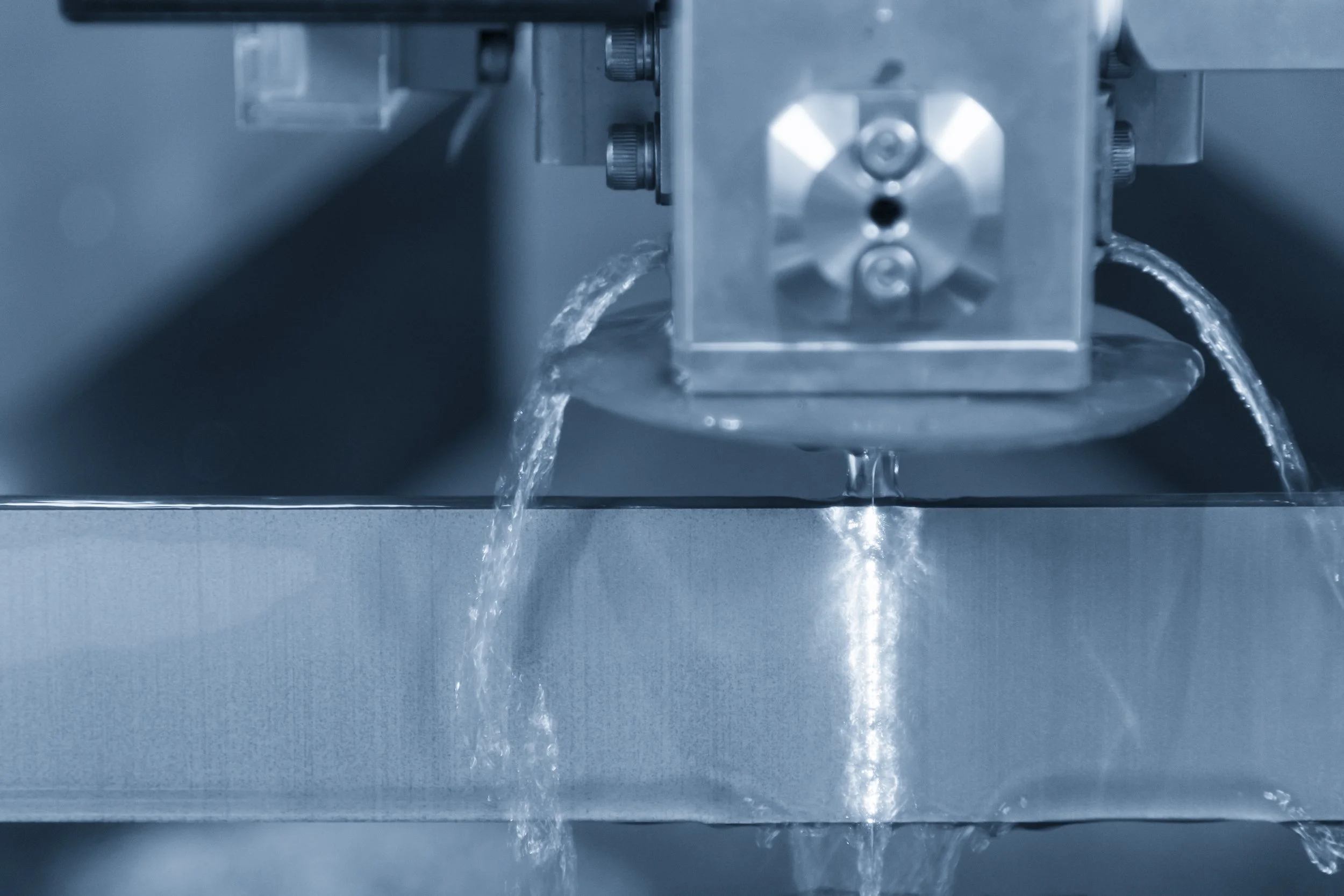

The Contour Method

Merits

Uses standard workshop equipment

Inexpensive

Cross-section map of direct stress

Resolves 2 mm length-scale stresses

Multiple stress components with multiple cuts and multiple methods

Can leverage other methods

Insensitive to microstructure

Limitations

Destructive

Electrical conducting materials

Max cut area depends on size of wire EDM machine (typically 0.6 m x 1.0 m)

Direct stress normal to cut face

Quality of wire EDM cut surface

Errors from elastic bulging, plasticity and data analysis

Surface Hole Drilling

Merits

ASTM E837 Standard

Portable for field use

Low cost and quick

In-plane stresses near to surface

Depth profiling up to 2 mm

Optical techniques available

Limitations

Local damage

Flat and smooth surfaces

Locations remote from geometric features

Plasticity errors for stresses > 60% yield

Needs skilled practitioner

X-ray Diffraction

Merits

International Standard

Portable for field use

Low cost and quick

No damage

In-plane stresses at surface

Depth profiling up to 1 mm

Limitations

Crystalline materials

Small grains for good sampling

Best for isotropic microstructure

Local surface curvature error

High surface roughness error

Needs skilled practitioner

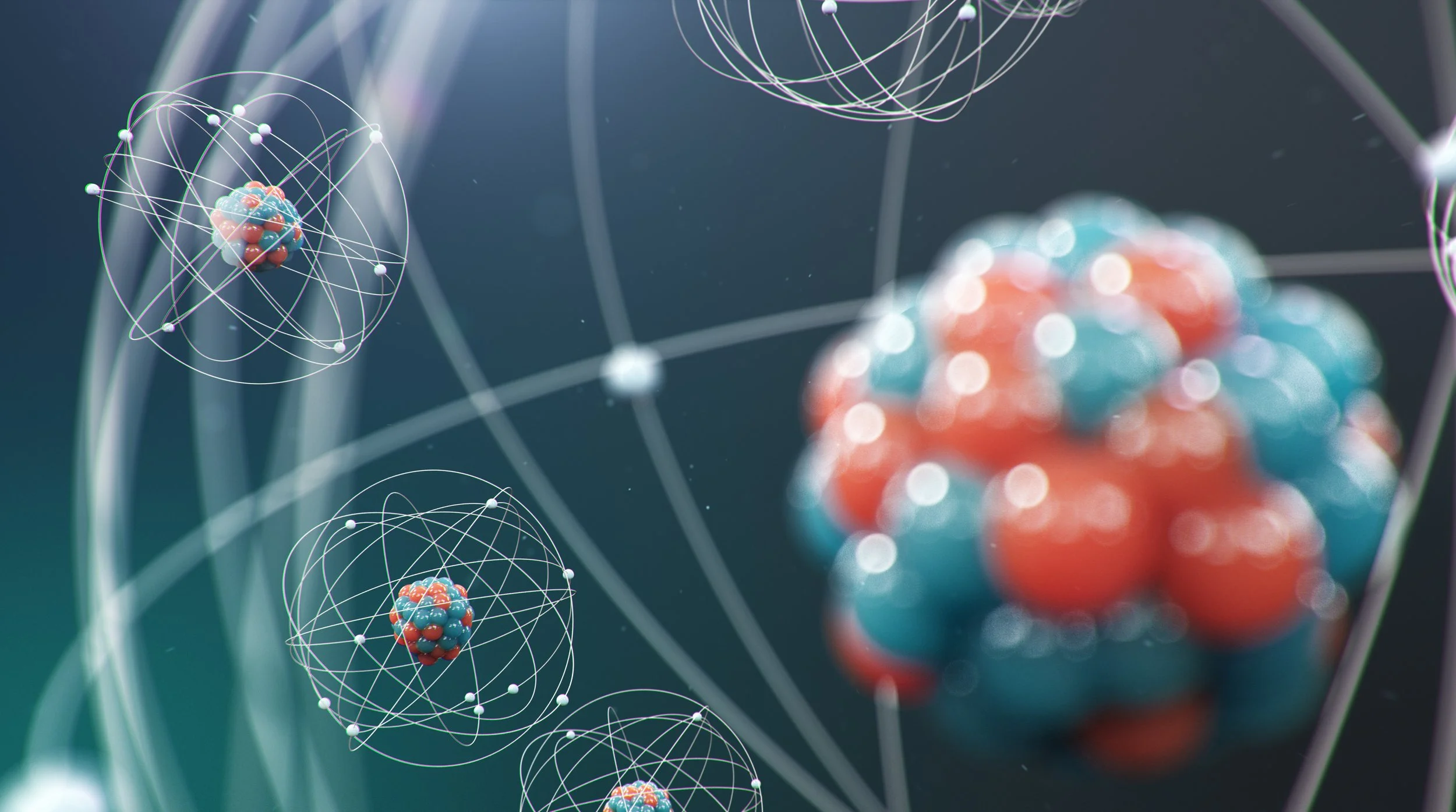

Neutron Diffraction

Merits

International Standard

Non-destructive

Can measure full stress tensor

Volumetric mapping

35 mm steel, 100 mm Aluminium

Limitations

Crystalline materials

Expensive - needs neutron source

Needs zero stress reference

Needs skilled practitioner

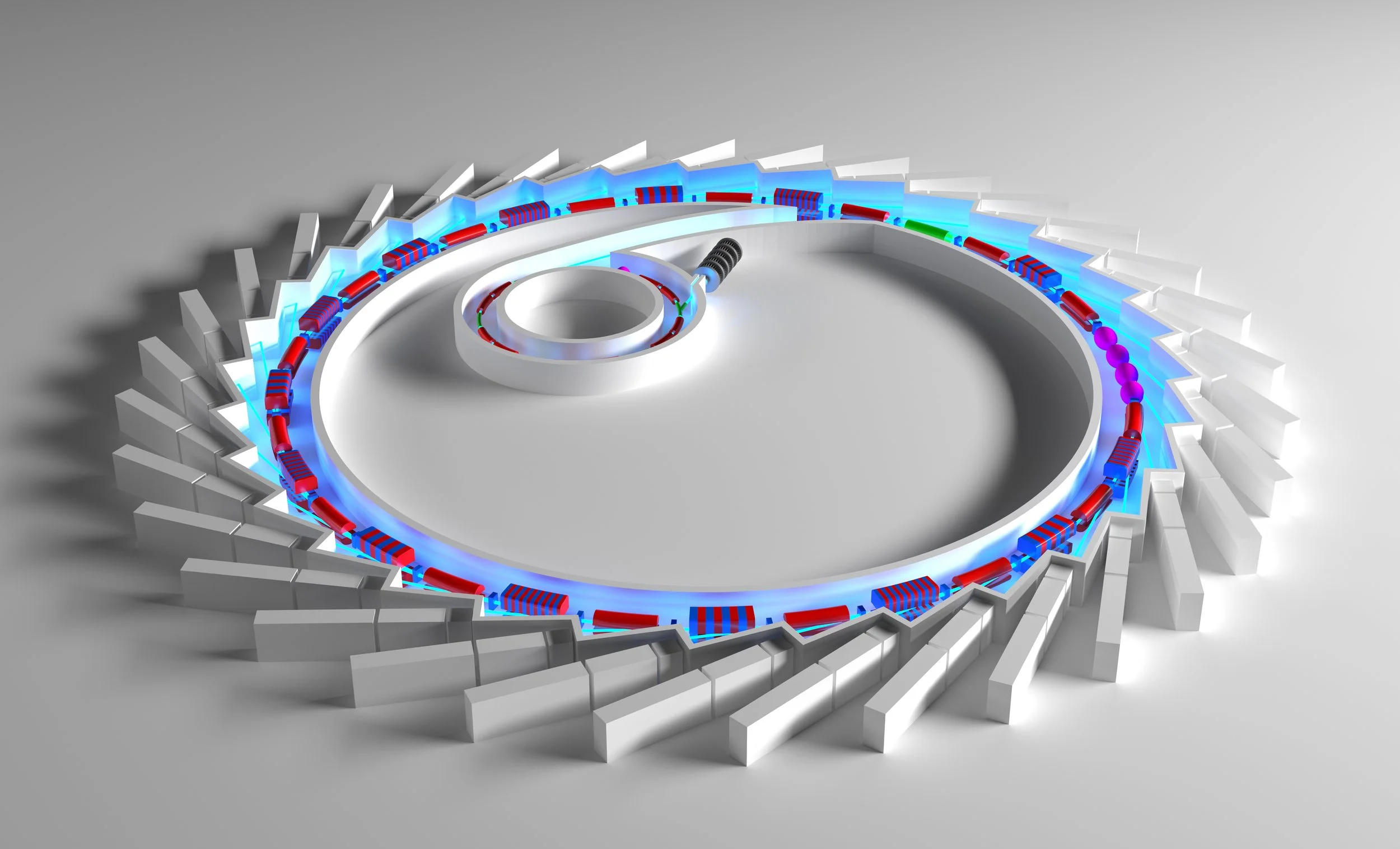

Synchrotron Diffraction

Merits

Non-destructive

In-plane stresses

Volumetric mapping

Fast acquisition

35 mm steel in transmission

Limitations

Crystalline materials

Expensive - needs synchrotron source

Needs zero stress reference

Data intensive

Needs skilled practitioner

Hybrid Methods

Limitations

Uncertainties can propagate

Needs skilled practitioner

Merits

Powerful combinations of methods

(e.g. Contour + XRD)More stress tensor data

More volumetric coverage

Confidence from cross-comparison of results

The Slitting Method

Merits

Laboratory method

Applicable to many materials

1-D line profile of direct stress through the thickness of prismatic shaped specimens

Good length-scale resolution of stresses

Limitations

Destructive

Gives average stress across width

Plasticity error when stresses are high

Sensitive to data analysis